UNMASKING PURITY: THE CRITICAL ROLE OF IMPURITY PROFILING AND CHARACTERIZATION

Short Communication - (2023) Volume 12, Issue 3

Introduction

In the realm of pharmaceuticals, ensuring the purity and quality of drug formulations is paramount. Impurity profiling and characterization, a rigorous analytical process, stand as a linchpin in this endeavour. This discipline involves the identification, quantification, and characterization of impurities that may be present in pharmaceutical products. These impurities, which can arise from various sources, have the potential to impact the safety and efficacy of the drug. This essay explores the pivotal role of impurity profiling and characterization in pharmaceutical quality control, emphasizing its significance in upholding the highest standards of patient safety and therapeutic efficacy.

Description

Pharmaceutical Impurities in pharmaceutical products encompass a broad range of substances beyond the active pharmaceutical ingredient (API). These impurities may originate from various sources, including raw materials, synthesis processes, and degradation over time. They can manifest as organic or inorganic compounds, related substances, or even residual solvents. While some impurities may be benign, others have the potential to be harmful, affecting the safety and efficacy of the drug. Impurity profiling and characterization aims to differentiate and quantify these impurities, providing crucial insights into their nature and potential impact.

The presence of impurities in pharmaceutical products carries inherent risks. Some impurities can lead to adverse effects, allergic reactions, or even toxicological consequences. Others may alter the pharmacokinetics or pharmacodynamics of the drug, affecting its therapeutic efficacy. Impurity profiling and characterization serve as a safeguard against such risks. By identifying and quantifying impurities, pharmaceutical scientists can establish acceptable limits and take appropriate measures to mitigate potential harm to patients.

Understanding and controlling impurities are integral to pharmaceutical manufacturing processes. Impurity profiling offers critical feedback to process chemists, enabling them to refine synthesis methods and purification techniques. By pinpointing the sources of impurities, researchers can implement process modifications to minimize their formation. This iterative approach to process optimization not only improves product quality but also enhances the overall efficiency and cost-effectiveness of drug manufacturing.

The pharmaceutical industry operates within a stringent regulatory framework. Regulatory agencies around the world, such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA), set forth specific guidelines and requirements for impurity assessment and control. Compliance with these standards is non-negotiable, as it ensures that pharmaceutical products meet the highest quality and safety standards. Impurity profiling and characterization serve as a cornerstone in meeting these regulatory requirements, demonstrating the industry’s commitment to patient safety and product efficacy.

Over time, pharmaceutical products may undergo chemical changes due to factors such as temperature, humidity, and exposure to light. These changes can lead to the formation of degradation products, which may act as impurities. Impurity profiling plays a vital role in stability testing, enabling researchers to identify and quantify these degradation products. By monitoring impurities over time, pharmaceutical companies can establish appropriate storage conditions and shelf-life specifications, ensuring that products maintain their quality and efficacy throughout their intended lifespan [1-4].

Conclusion

Impurity profiling and characterization represent a linchpin in pharmaceutical quality control, underscoring the industry’s commitment to patient safety and therapeutic efficacy. By identifying, quantifying, and characterizing impurities, pharmaceutical scientists gain critical insights into their nature and potential impact on patients. This rigorous analytical process guides process optimization, ensures regulatory compliance, and safeguards the long-term quality of pharmaceutical products.

Acknowledgement

The authors are very thankful and honoured to publish this article in the respective Journal and are also very great full to the reviewers for their positive response to this article publication.

Conflict Of Interest

We have no conflict of interests to disclose and the manuscript has been read and approved by all named authors.

References

- Choi H, Han H. Nanomedicines: current status and future perspectives in aspect of drug delivery and pharmacokinetics. J Pharm Investig 2018; 48: 43.

- Collins AR, Annangi B, Rubio L, et al. High throughput toxicity screening and intracellular detection of nanomaterials. Wiley Interdiscip Rev Nanomed Nanobiotechnol 2017; 9:e1413.

- Donaldson K, Stone V, Tran CL, et al. Nanotoxicology. Occup Environ Med 2004; 61:727-728.

- Fadeel B, Feliu N, Vogt C, et al. Bridge over troubled waters: understanding the synthetic and biological identities of engineered nanomaterials. Wiley Interdiscip Rev Nanomed. Nanobiotechnol 2013; 5:111-129.

Author Info

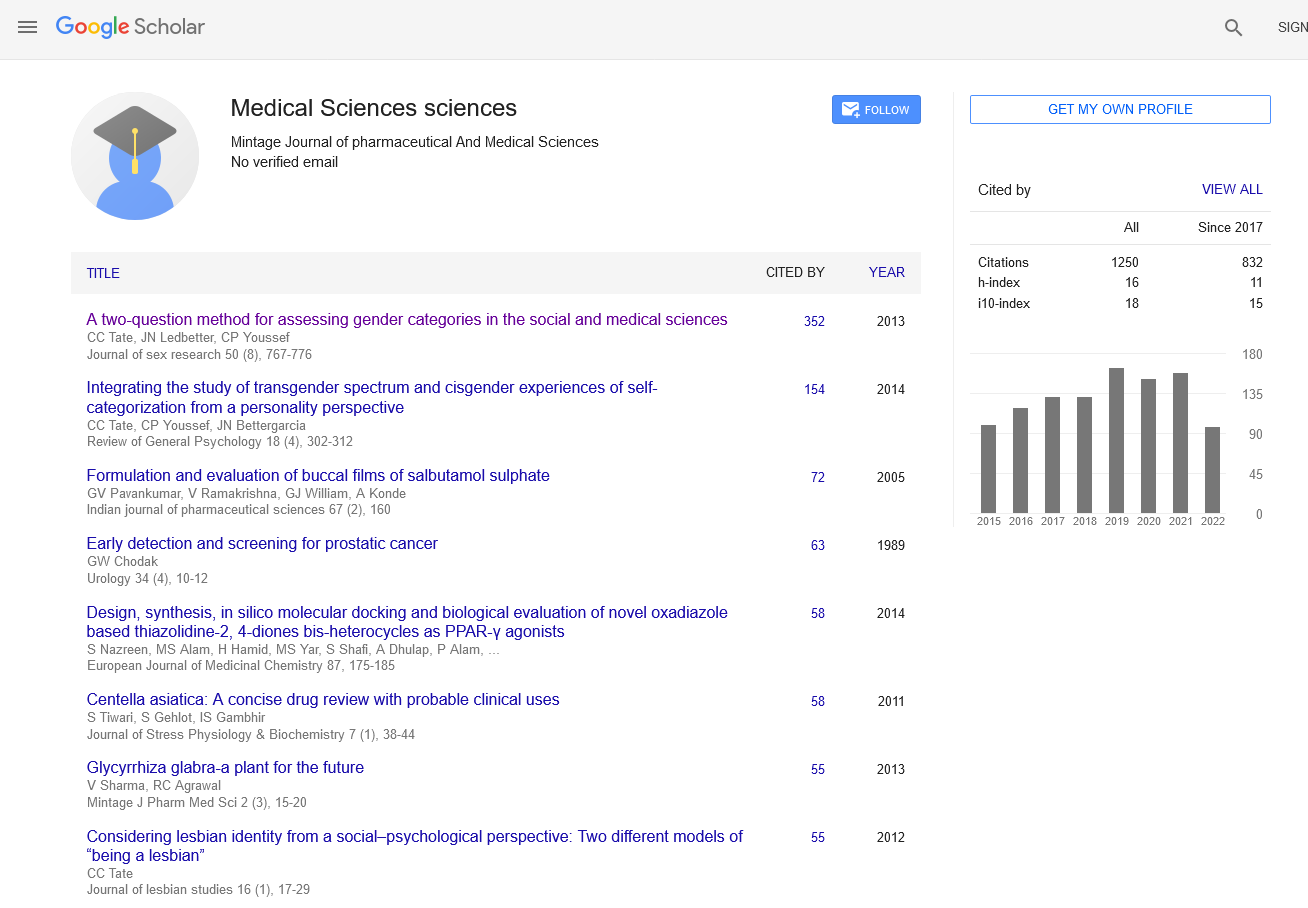

Scarlett Gemel*Received: 29-Aug-2023, Manuscript No. mjpms-23-117153; , Pre QC No. mjpms-23-117153(PQ); Editor assigned: 31-Aug-2023, Pre QC No. mjpms-23-117153(PQ); Reviewed: 14-Aug-2023, QC No. mjpms-23-117153; Revised: 19-Aug-2023, Manuscript No. mjpms-23-117153(R); Published: 26-Aug-2023, DOI: 10.4303/2320-3315/236060

Copyright: This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

ISSN: 2320-3315

ICV :81.58